qmtcheck test and quality control station

For integration into a customer process

Test and quality control systems integrator

The qmtcheck test and quality control stations are integrated into a machine or customer equipment.

QMT stations are integrated directly into the heart of our customers' manufacturing processes. Fully automatic or semi-automatic, they allow process automation or quality control to guarantee zero defects and the reduction of manufacturing scrap.

qmt is a solution provider, we are committed to results. To meet the needs of our customers, qmt offers 4 delivery programs: from standard product to tailor-made solution ( qmtm4u ) through customization ( qmtf4u )

qmt at the service of its customers with 34 years of success

In 1991, qmt developed Multimicro, a motorized image analyzer with automatic microhardness measurement

Our historyParticular expertise for appearance control

- Stations for measurement, testing or quality control

- Multi-inspection: acoustic, optical, etc.

- Dimensional measurements, conformity, nomenclature (assembly of several parts, etc.), appearance (scratches, dents, stains, etc.)

- Acoustic or vibration analysis

qmt customization programs

measure

Solution according to specifications

charges

Ease of integration into customer processes

- Signal acquisition and processing equipment

- Data processing, supervision and management software

- Automation, mechanical and electrical integration

- Communication and data management

qmt addresses the specificities of the medical market

- Automation, mechanical and electrical integration

- Definition of requirements in collaborative mode

- Completion of qualifications according to medical standards

Example of a medical measuring station

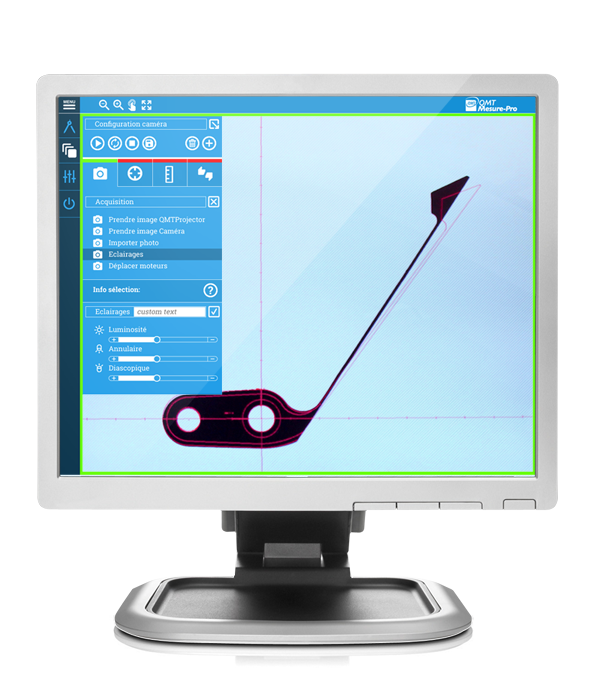

All solutions are based on unique software functions

For optical control

To increase production yields

and the quality of the parts

For aesthetic control

For acoustic and vibration control

Integration into our customers' machines to automate testing and control

Five product lines

Acquisition and processing of signals with software, hardware, acquisition hardware and sensors

Autonomous, they are dedicated to measurement for control by sampling in production and for the laboratory

Completely automatic from the feeding of the parts to the control: any non-compliant part is thus ejected and therefore the quality control is 100% guaranteed

qmtembedded

They operate autonomously with acquisition, processing and control to supervise and automate

qmtbench

physical systems allowing to put a product in configurable and controlled conditions of use in order to observe and measure its behavior

The high-performance measurement that is easy to implement

The control program is carried out using an intuitive interface comprising program templates, standard control equations and functions that automatically detect and offer the characteristics of the part. The operator can thus select the controls and define the tolerances, the control program is thus created automatically

- Ease of use and intuitiveness

- Wide range of measurement functions

- Efficient communication & synchronization with machines

- QMTInspect specific functions for use in sorting machines